Engineering

ELECTRIC RADIANT-TYPE ALUMINIUM HOLDING FURNACE (EH Model)

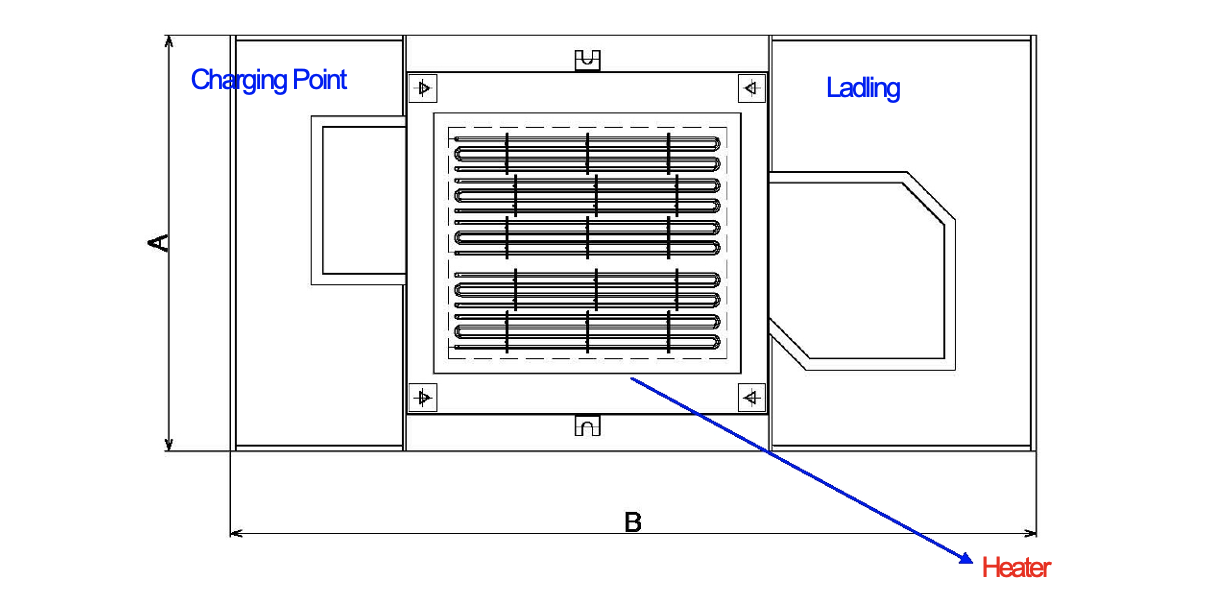

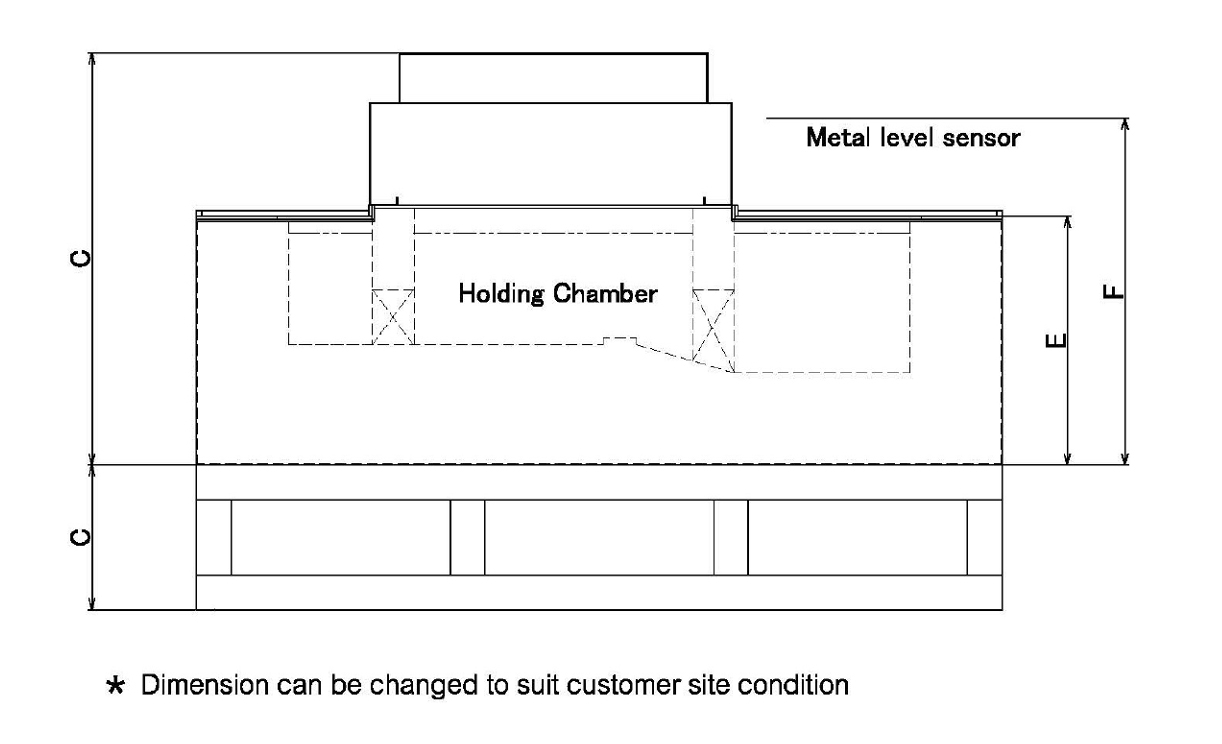

The EH furnace is composed of 4 chambers: heating, melt charging, melt distributing and temperature measuring chamber. It is designed to be a holding furnace especially for the aluminium die casting hot charge process. The furnace con- sists of highly insulating boards (5 layers) and equipped with molten aluminium level detector, melt and atmospheric temperature control unit. It is designed not only being an energy-saving, labor-saving and space-saving furnace but also a safe fully automatic furnace.

1. SUPERIOR ALUMINIUM MELT QUALITY

This furnace is Installed with "Silicon Carbide" Electric Heaters which do not generate oxidation and molten metal temperature control below -7 °C to +2°C of set pointing

2. LOW ENERGY COST (DURING OPERATION)

Thermal efficiency in electric furnace is very high compared to conventional burner-type furnaces. (almost 1/5)

3. SUPERIOR WORKING ENVIRONMENT

No noise, no exhaust gas and no heat radiation from the furnace body.

4. LOW MAIN TENANCE COST

Built to withstand harsh conditions, it is possible for the furnace to be free of repairs for more than 4 years.

5. "BATH TUB" DESIGN

With a "bath tub", the furnace refractories are cast in one operation without any joints. Since there are no joints during refractory casting, it will be difficult for refractories.

EH Furnace Specification

| Type | Holding Capacity (Kg) |

Electrical Power (KW) |

Electric Power on casting (KWH) |

Electric Power on holding (KWH) |

|---|---|---|---|---|

| EH-500 | 500 | 9 | 5 | 3 |

| EH-700 | 700 | 10 | 7 | 3.5 |

| EH-1000 | 1,000 | 12 | 9 | 4.5 |

| EH-1200 | 1,200 | 15 | 11 | 5 |

| EH-1500 | 1,500 | 18 | 13 | 6.5 |

| EH-2000 | 2,000 | 27 | 18 | 8.5 |

EH Furnace Specification

| EH-500 | EH-700 | EH-800 | EH-1200 | EH-2000 | |

|---|---|---|---|---|---|

| A | 1,260 | 1,430 | 1,460 | 1,500 | 1,500 |

| B | 1,710 | 2,155 | 2,310 | 2,890 | 3,130 |

| C | 1,230 | 1,230 | 1,230 | 1,450 | 1,500 |

| D | HEIGHT CAN BE MADE ADJUSTABLE | ||||

| E | 665 | 665 | 665 | 880 | 930 |

| F | 965 | 965 | 965 | 1,080 | 1,230 |